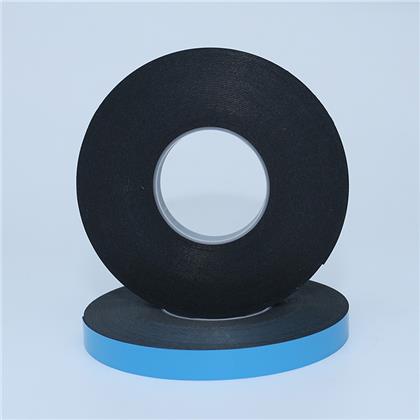

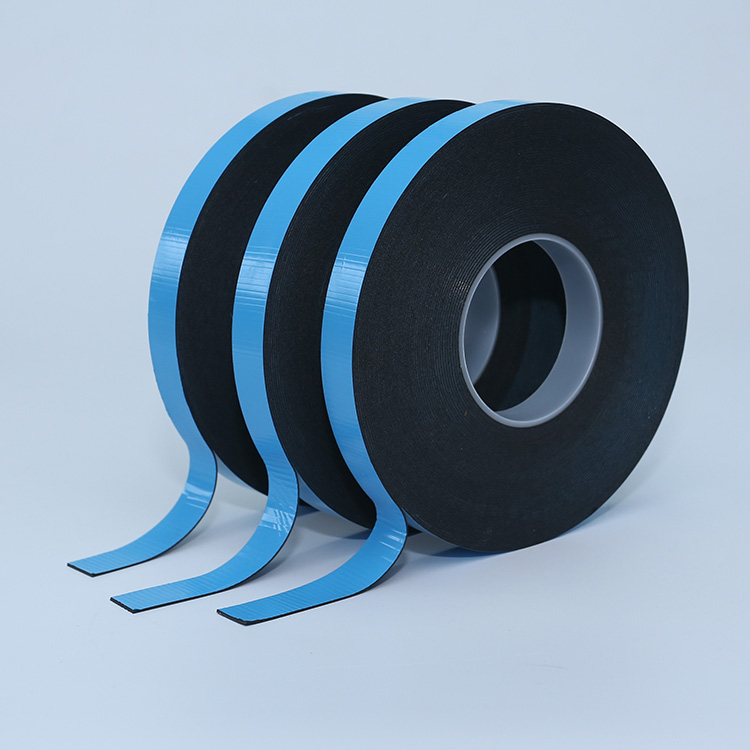

Blue film Black PE Double Sided Foam Adhesive Tape

Lixin 66080is a high performance double-sided foam bonding tape. The product is black. The Polyethylene foam is predominantly closed celled. An acrylic pressure sensitive adhesive is coated on both sides, and the product has a white paper release liner. The material can be supplied with a film liner facilitating automated application.

![]()

High Performance Black PE Double Sided Foam Adhesive Tape

PRODUCT DESCRIPTION

Lixin 66080is a high performance double-sided foam bonding tape. The product is black. The Polyethylene foam is predominantly closed celled. An acrylic pressure sensitive adhesive is coated on both sides, and the product has a white paper release liner. The material can be supplied with a film liner facilitating automated application.

![]()

|

Colours Black

|

|

Adhesive Acrylic

|

|

Liner Paper release liner can be supplied with film liner

|

|

Carrier PE Foam

|

|

Thickness 0.5; 0.8,1.0mm

|

|

Availability

Asia/EU/NA

|

|

APPLICATIONS ·Photovoltaic (PV) module frame bonding. ·Automotive design systems. ·External automotive emblem bonding. ·White goods panel / frame bonding.

|

|

PRODUCT BENEFITS ·Pre-determined dimensional sealant reduces waste / clean to use. ·May be used with Perspex and Polycarbonate. ·No known hazards associated with this product. ·Suitable for indoor and outdoor environments. ·Resistance to abrasion, corrosion and moisture. ·Very good ultraviolet {UV} light resistance. ·Paper release liner, reducing dimensional change during application. ·Good resistance to dilute acids and alkalis. ·Coated on both sides with a high quality pressure sensitive acrylic adhesive. ·Minimum 20% compression required to effect a water seal. ·Shelf life of 1 year from date of dispatch. ·Application temperature: +10°C to +40°C. ·Service temperature: -40°C to +100°C. |

![]()

| product | Backing | adhesive | Total Thickness | Initial Tack | Peel Adhesion | Holding power |

Replace

Brand tape

|

||

| (um) | (mil) | (#) | N/in | ASTM D-3330 (oz/in) | |||||

| 65010 | EVA | Solvent Acrylic | 1500 | 6.0 | 12↑ | 12↑ | 36 | 24hour↑/80℃ | / |

| 65015 | EVA | Solvent Acrylic | 2000 | 8.0 | 12↑ | 12↑ | 36 | 24hour↑/80℃ | / |

| 65020 | EVA | Solvent Acrylic | 2500 | 10.0 | 12↑ | 12↑ | 36 | 24hour↑/80℃ | / |

| 66015 | PE foam | Solvent Acrylic | 150 | 6.0 | 18↑ | 20↑ | 60 | 24hour↑/80℃ | Sekisui5215PSB/Nitto57115 |

| 66020 | PE foam | Solvent Acrylic | 200 | 8.0 | 18↑ | 20↑ | 60 | 24hour↑/80℃ | Sekisui5200PS/Nitto57120 |

| 66025 | PE foam | Solvent Acrylic | 250 | 10.0 | 18↑ | 20↑ | 60 | 24hour↑/80℃ | Sekisui5225PSB/Nitto57125 |

| 66025T | PE foam | Solvent Acrylic | 250 | 10.0 | 16↑ | 15/10↑ | 45/30 | 24hour↑/80℃ | tesa62945 |

| 66030 | PE foam | Solvent Acrylic | 300 | 12.0 | 18↑ | 20↑ | 60 | 24hour↑/80℃ | Sekisui5230PSB/teraoka7813 |

| 66030T | PE foam | Solvent Acrylic | 300 | 12.0 | 16↑ | 15/10↑ | 45/30 | 24hour↑/80℃ | tesa62946 |

| 66040 | PE foam | Solvent Acrylic | 400 | 16.0 | 18↑ | 20↑ | 60 | 24hour↑/80℃ | Sekisui5240NSB |

| 66050 | PE foam | Solvent Acrylic | 500 | 20.0 | 18↑ | 20↑ | 60 | 24hour↑/80℃ | / |

| 66060 | PE foam | Solvent Acrylic | 600 | 24.0 | 18↑ | 20↑ | 60 | 24hour↑/80℃ | Sekisui5260NSB |

| 66080 | PE foam | Solvent Acrylic | 800 | 32.0 | 18↑ | 20↑ | 60 | 24hour↑/80℃ | Sekisui5290NSB |

| 66100 | PE foam | Solvent Acrylic | 1000 | 40.0 | 18↑ | 20↑ | 60 | 24hour↑/80℃ | Sekisui52110NSB |

| 66100V(Low voc) | PE foam | Solvent Acrylic | 1000 | 40.0 | 18↑ | 20↑ | 60 | 24hour↑/80℃ | / |

| 66150 | PE foam | Solvent Acrylic | 1500 | 60.0 | 18↑ | 20↑ | 60 | 24hour↑/80℃ | / |

| 66200 | PE foam | Solvent Acrylic | 2000 | 80.0 | 18↑ | 20↑ | 60 | 24hour↑/80℃ | / |

| 66300 | PE foam | Solvent Acrylic | 3000 | 120.0 | 18↑ | 20↑ | 60 | 24hour↑/80℃ | / |

![]()

![]()

- Previous:Double Coated Pressure Sensitive Adhesive Foam tape

- Next:High Performance White PE Double Sided Foam Adhesive Tape 1.5mm