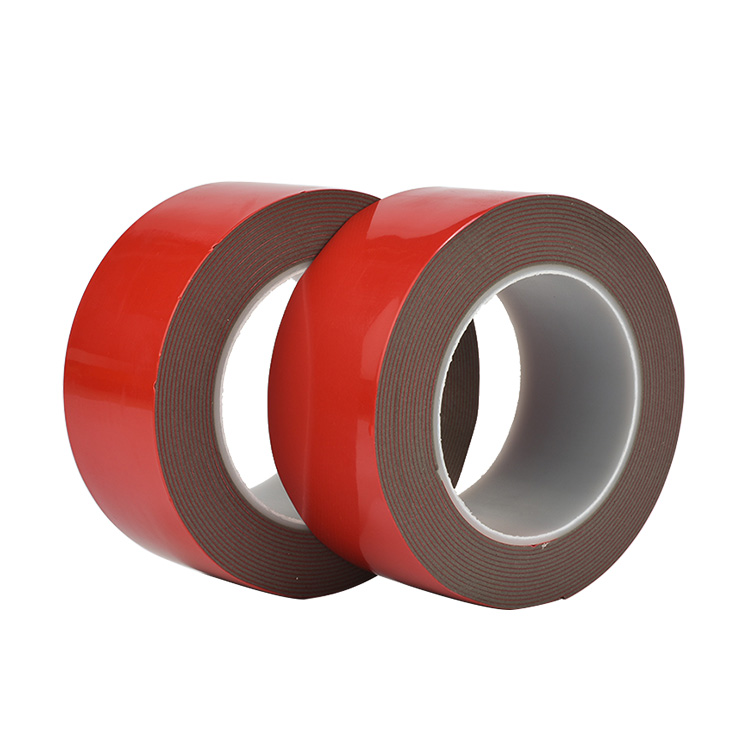

Grey Acrylic Foam Tape-1.2mm

2021/10/9

6612G is a highly conformable, strong double sided acrylic foam tape with a release liner on one side. The product is used for permanent bonding of materials such as metals, glass and some plastics, in interior and exterior applications.

![]()

Acrylic Foam Tape (AFT) - 1.2mm, Grey, Conformable, Higher Temperature

PRODUCT DESCRIPTION

6612G is a highly conformable, strong double sided acrylic foam tape with a release liner on one side. The product is used for permanent bonding of materials such as metals, glass and some plastics, in interior and exterior applications.

![]()

|

Colours

Grey

|

|

Adhesive Acrylic

|

|

Liner Red siliconised Polyethylene (SPE) |

|

Carrier Acrylic Foam

|

|

Thickness 1.2mm

|

|

Availability

Asia/EU/NA |

|

APPLICATIONS ·Panel fixation, metal stiffener and reinforcement bar bonding: doors, lifts, trailers, cabinets, traffic signs, etc. ·The bonding of emblems and trims in the automotive industry. ·The bonding of electronics components.

|

|

PRODUCT BENEFITS

·Withstands expansion and contraction of materials without loss of adhesion due to its visco-elastic properties. |

|

Features ·Fast and easy assemblage ·Great conformability and stretching ·Good performance in dynamic shear ·Good moisture and chemical resistance, ideal for exterior use ·Creates an environment-friendly seal when bonding ·Resists UV light for long term outdoor durability |

|

|

![]()

|

Acrylic Foam Technical Data Sheet |

|||||||||||

| No. | Base Material | Thickness(mm) | Release Liner | 180° Peeling Strength 20min(N/24mm) | Temperature Resistance | ||||||

| 6602G | Grey acrylic foam | 0.25 | White Release paper | 18 | -20℃~160℃ | ||||||

| 6604G | Grey acrylic foam | 0.4 | Red PE film | 25 | -20℃~160℃ | ||||||

| 6606G | Grey acrylic foam | 0.64 | Red PE film | 28 | -20℃~160℃ | ||||||

| 6608G | Grey acrylic foam | 0.8 | Red PE film | 30 | -20℃~160℃ | ||||||

| 6612G | Grey acrylic foam | 1.2 | Red PE film | 30 | -20℃~160℃ | ||||||

| 6615G | Grey acrylic foam | 1.5 | Red PE film | 25 | -20℃~160℃ | ||||||

| 6620G | Grey acrylic foam | 2 | Red PE film | 20 | -20℃~160℃ | ||||||

| 6602W | White acrylic foam | 0.25 | White Release paper | 23 | -20℃~160℃ | ||||||

| 6604W | White acrylic foam | 0.4 | Red PE film | 25 | -20℃~160℃ | ||||||

| 6606W | White acrylic foam | 0.64 | Red PE film | 25 | -20℃~160℃ | ||||||

| 6608W | White acrylic foam | 0.8 | Red PE film | 25 | -20℃~160℃ | ||||||

| 6612W | White acrylic foam | 1.2 | Red PE film | 25 | -20℃~160℃ | ||||||

| 6615W | White acrylic foam | 1.5 | Red PE film | 25 | -20℃~160℃ | ||||||

| 6620W | White acrylic foam | 2 | Red PE film | 20 | -20℃~160℃ | ||||||

| 66005T | Transparent acrylic | 0.05 | White Release paper | 12 | -20℃~160℃ | ||||||

| 66013T | Transparent acrylic | 0.13 | White Release paper | 16 | -20℃~160℃ | ||||||

| 66025T | Transparent acrylic | 0.25 | White Release paper | 20 | -20℃~160℃ | ||||||

| 6605T | Transparent acrylic | 0.5 | Red PE film | 20 | -20℃~160℃ | ||||||

| 6608T | Transparent acrylic | 0.8 | Red PE film | 22 | -20℃~160℃ | ||||||

| 6610T | Transparent acrylic | 1 | Red PE film | 25 | -20℃~160℃ | ||||||

| 6620T | Transparent acrylic | 2 | Red PE film | 25 | -20℃~160℃ | ||||||

| 6602B | Black acrylic foam | 0.2 | PET film | 20 | -20℃~160℃ | ||||||

| 66025B | Black acrylic foam | 0.25 | PET film | 23 | -20℃~160℃ | ||||||

| 6603B | Black acrylic foam | 0.3 | PET film | 28 | -20℃~160℃ | ||||||

| 6604B | Black acrylic foam | 0.4 | Red PE film | 30 | -20℃~160℃ | ||||||

![]()

![]()

Lixin Adhesive Technology (Shanghai) Co.,Ltd All rights reserved ICP:19034273-1 Disclaimer